Dealing with fluids that have a high concentration of particles, viscous contaminants, or even gelatinous impurities? If your industrial processes often encounter these challenges, then depth filtration is a method you need to understand. It’s not just a filter; it’s a highly efficient and robust solution critical for maintaining purity and operational efficiency across a myriad of industrial applications.

What Exactly is Depth Filtration?

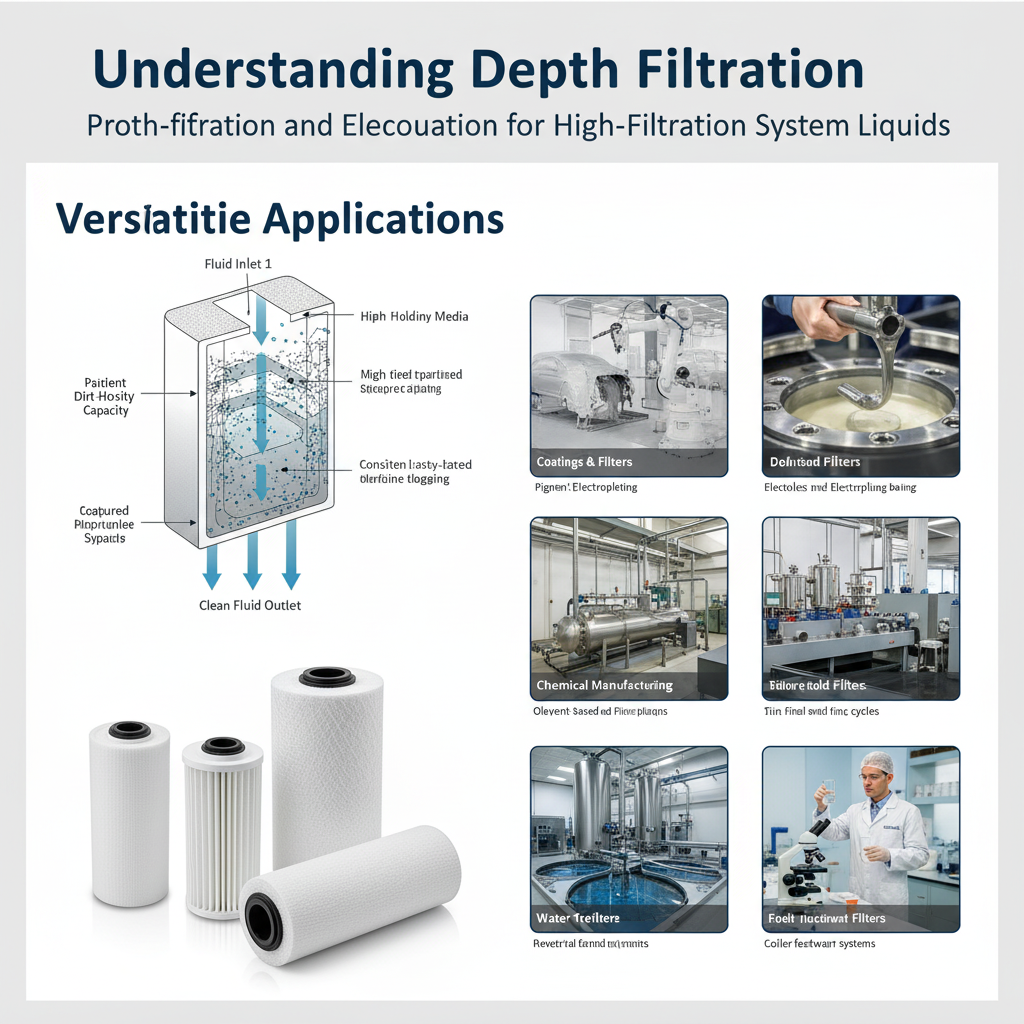

At its core, depth filtration fundamentally differs from surface filtration. While surface filters act like a sieve, trapping particles primarily on their outermost layer, [cite_start]depth filters employ a unique, gradient-density media structure that captures contaminants throughout the entire cross-section of the filter material[cite: 1]. Imagine a complex, three-dimensional maze where particles are progressively trapped deeper within the filter as the fluid flows through.

[cite_start]This volumetric particle retention mechanism is the key to their superior performance. It allows depth filters to boast an exceptionally high dirt-holding capacity and remarkable resistance to premature clogging[cite: 2]. This means fewer filter change-outs, reduced downtime, and more consistent processing.

Typically, these robust filters are constructed from various materials, each chosen for specific applications and chemical compatibilities. Common materials include melt-blown polypropylene, intricate glass fibers, or precisely wound yarns. Their inherent strength and design allow them to maintain stable differential pressure and consistent flow rates over extended service intervals. This characteristic makes them an absolutely essential component in high-reliability process filtration systems where consistent performance is non-negotiable.

Versatile Applications Across Diverse Industries

Due to their exceptional ability to handle challenging fluids, depth filters are not just an option but often a necessity, widely applied across a spectrum of industries. They frequently serve as crucial pre-filters in multi-stage liquid filtration systems, protecting more sensitive downstream filters and equipment from premature wear and tear.

Let’s explore some key sectors where depth filtration plays a pivotal role:

-

Coatings and Plating: In the delicate world of paints, coatings, and surface finishing, purity is paramount. Depth filters are indispensable for the clarification of pigment dispersions and resins. Furthermore, they act as critical pre-filters in both electroless and electroplating baths for metals like nickel, tin, gold, and copper, ensuring a flawless finish.

-

Chemical Manufacturing and Processing: The chemical industry often deals with aggressive and complex fluid streams. Depth filters are highly effective at removing gelatinous contaminants in polymer or adhesive manufacturing processes. They are also vital for

-

Water Treatment and Utilities: From industrial cooling systems to advanced purification, water quality is critical. Depth filters excel at removing metal fines and scale in cooling water or during CIP rinse cycles. Crucially, they are also employed in pre-RO filtration setups to protect delicate RO membranes from colloidal fouling, extending membrane life and efficiency

-

General Industrial: Depth filters are also invaluable for purifying high-viscosity liquids that present a wide range of particle sizes and are used for condensate filtration in boiler feedwater recovery systems.

The Unseen Advantage

By incorporating depth filtration into your process, you’re not just installing a component; you’re implementing a foundational solution that enhances product purity, extends equipment lifespan, reduces operational costs, and ultimately ensures that your production processes run smoothly and efficiently. If you’re looking for a dependable answer to your complex filtration needs, depth filtration is undoubtedly a technology to consider.

7 thoughts

halo

teest

oi

l

Test

Bagus

hai kaka