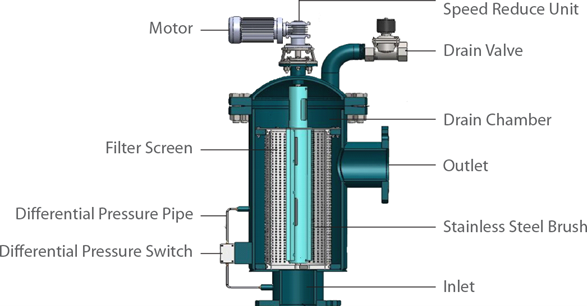

Automated Self-Cleaning Filtration System with a wedge wire screen is a modern solution designed to tackle industrial liquid filtration challenges.

These systems are ideal for environments with high solids, high viscosity, or batch processes, where traditional filtration methods might be inefficient.

Why Choose an Automated System?

Unlike conventional filters, these systems are equipped with self-cleaning mechanisms, such as scrapers or backflushing, that operate automatically This allows for continuous operation without needing to stop the flow for cleaning or media replacement The key benefits include:

- Low Maintenance: Reduces manual intervention and labor costs.

- High Efficiency: Ensures a stable flow rate even when handling heavy contaminant loads.

- Durable and Strong: Constructed from durable stainless steel (SS304, SS316L) that resists corrosion and pressure shocks.

How Does It Work?

The core element of this system is the

wedge wire screen, which is made from precision-welded V-profile stainless steel wire. This unique design creates a rigid, non-plugging surface with consistent slot openings for precise filtration.

The system is highly effective for various applications, such as paint and coating production, industrial wastewater pre-treatment, and chemical slurry clarification. Additionally, the system can be customized with features like differential pressure sensors or PLC integration for more advanced control.

With its ability to operate continuously with minimal maintenance, this automated filtration system offers improved operational reliability and lower long-term costs.

5 thoughts

halo

halo juga

chek

test

test2